HOME>

Product Information>

Inspection, Investigation and Diagnosis>

Main Lines> CRVICE ® Steel Pipe Column Crack Inspection System

Inspection/survey/diagnosis

CRVICE ® Steel pipe column crack inspection system

Patent pending

NEXCO Engineering Hokkaido Co., Ltd.Product Summary

NETIS登録番号 QS-230018-A

共同開発:(株)カナデビアエンジニアリング

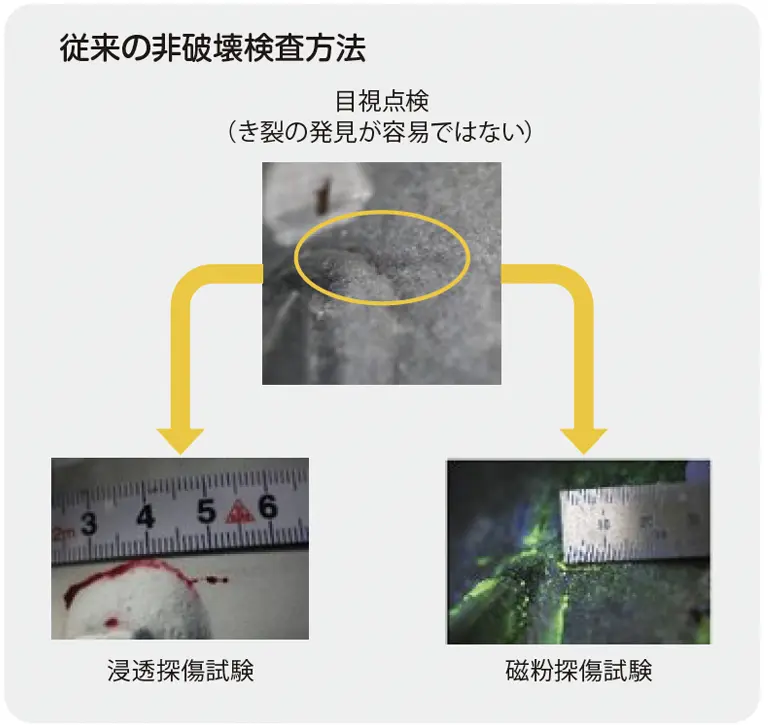

This is a non-destructive inspection system that can detect cracks without removing the plating or paint on the steel surface.

System Configuration

System overview

- We use non-destructive inspection methods.

- There is no need to remove the coating from the metal surface.

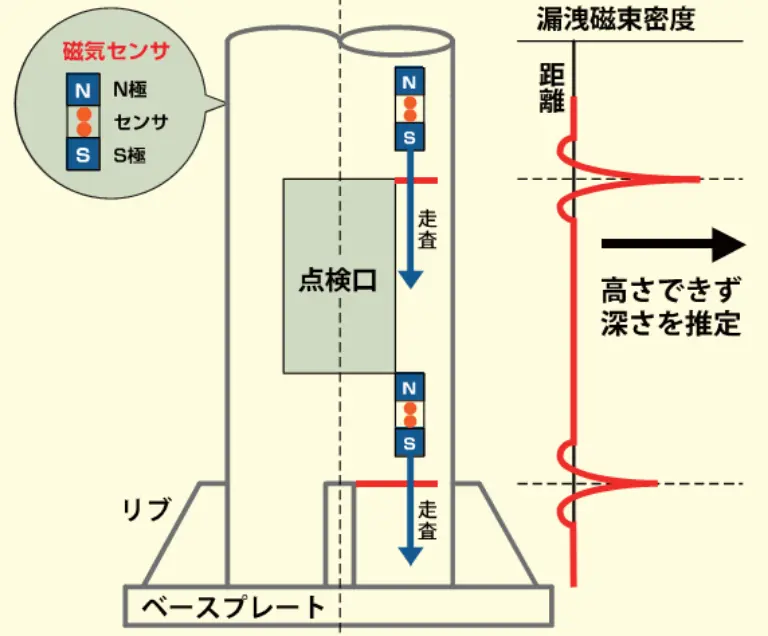

Inspection image using the leakage magnetic flux method

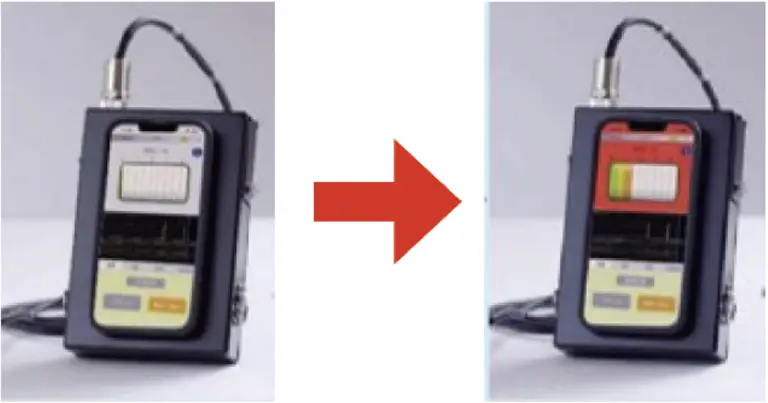

- When a crack is detected, the display will change color and sound and vibration will alert you.

- The crack depth dimension is displayed as the detection level on the display.

Image of crack detection

Features/Specifications

- It is small, lightweight and highly portable.

- 鋼管柱だけでなく橋梁などの鋼構造物の点検にも適応可能。

- A special tool is used to ensure smooth operation of the scanning of the detection area.

- The device can be used continuously for 4 hours by battery, and the battery can be easily replaced.

- 点検調書を簡単に作成・保存が可能です。

・検知レベル、外観写真などを調書として保存。 - 漏洩磁束法・渦電流法の2種類の点検方法で母材・溶接部の微小なき裂も検出。

Crack inspection status

Inspection records can be easily created and saved.

※「鋼管柱き裂点検システム CRVICE(クレビス)」は㈱ネクスコエンジニアリング北海道と㈱カナデビアエンジニアリングの共同開発品です。

※協力:ACTUNI ㈱

Achievements (sales/construction/introduction)

Our company:

One