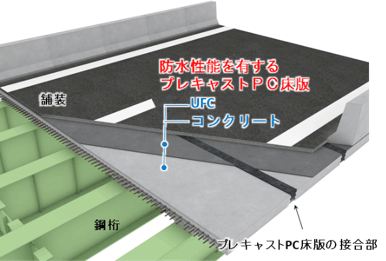

防水性能を有するプレキャストPC床版を開発

~高速道路リニューアルプロジェクトにおける工程短縮を目指し開発、実用化へ ~

令和2年4月1日

東日本高速道路株式会社

NEXCO東日本(東京都千代田区)は株式会社大林組(東京都港区)と共同で、高速道路リニューアルプロジェクトにおける床版取替工事の工程短縮および床版の耐久性向上を目指して、超高強度繊維補強コンクリート(UFC:Ultra High Strength Fiber Reinforced Concrete)を用いた防水性能を有するプレキャストPC床版を開発しました。

1 開発の経緯

安全・安心な高速道路サービスの提供のためには、工事規制の影響を極力減らすことが求められます。これは、高速道路リニューアルプロジェクトの床版取替工事でも同様であり、施工期間中の工事規制日数を少しでも減らすことが重要です。

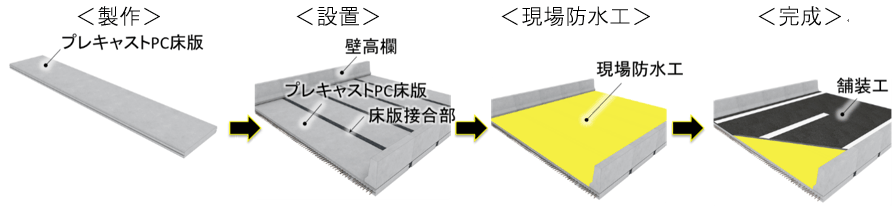

そこで、あらかじめ工場で製作するプレキャストコンクリートに防水性能を付与させることにより、現場の施工日数を短縮できると考え、平成30年4月から大林組と共同研究により開発を進めてきました。

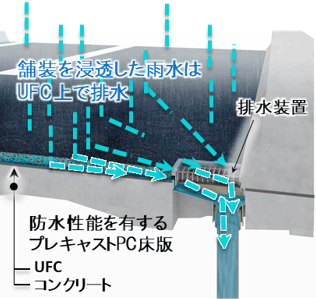

また、鉄筋コンクリート床版には、アスファルト舗装のひび割れや橋面排水装置の損傷から生じる 水の影響により、コンクリートや鉄筋の劣化が促進することがわかっており、床版内部に水を浸透させないことが重要となります。UFCの優れた遮水性能を活かすことによって、床版内部に水が浸透せず、耐久性の高い床版を実現させることができます。

(1)従来の工法

(2)新たな工法

2 技術の概要

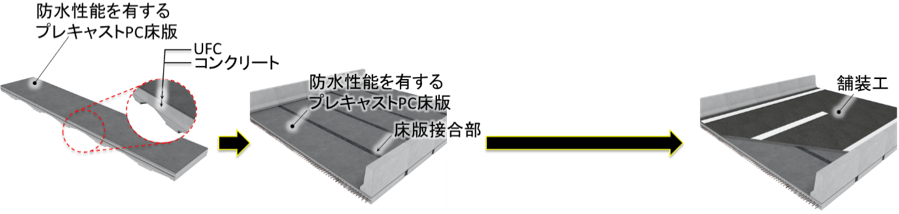

遮水性能に優れるUFCを、プレキャストコンクリートの製造および供用中の荷重作用などによってひび割れが生じない厚さ(2~5cm)で床版上面に接着し、床版内部への雨水の浸透を防止します。

UFCならびにプレキャストPC床版同士の接合部には、株式会社大林組が開発したスリムクリートRを採用し、防水性能を確保しております。

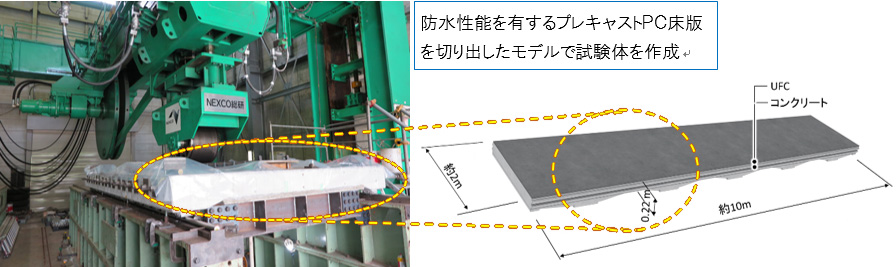

実物大の床版切り出しモデルを用いて、繰り返しの車両の影響を考慮した輪荷重走行試験を行い、下記の性能を確認しました。

- 従来のプレキャストPC床版と同等以上の疲労耐久性を有すること

- プレキャスト床版の普通部のコンクリートとUFCとの一体性が確保されていること

- 防水が保持されていること

3 今後の計画

様々な構造検討、性能確認実験および輪荷重走行試験により、プレキャストPC床版として十分な一体性、防水性能、強度および疲労耐久性を有することを確認しました。

今後、高速道路リニューアルプロジェクトにおいて、実橋への適用を検討していきます。

PDFファイルをご覧いただくには、AdobeSystems社のプラグインソフト「Acrobat Reader(日本語版)」が必要です。お持ちでない方は、こちらからダウンロード(無料)してご利用ください。

関連サイト・コンテンツ

料金・ルート検索、サービスエリア・パーキングエリアの情報をお探しの方はこちら。

リアルタイムの渋滞・規制情報をお探しの方はこちら。

災害時の通行止めなどの道路情報をお探しの方はこちら。