Innovation to provide sustainable Expressway

- Corporate Top

- CSR

- 2019 Featured Content

- Innovation to provide sustainable Expressway

Expressway efforts towards the establishment of long-term conservation of the (Expressway renewal project)

Of the 3,940 km of Expressway managed by the NEXCO EAST Group approximately 1,760 km have been in service for 30 to 50 years, and the number of large vehicles used is increasing year by year. Furthermore, about 70% of the total passes through the snowy regions and the amount of antifreeze sprayed reaches about 160,000 tons per year. Is in the situation where is occurring.

These are based, Expressway in order to fulfill its role as Japan's aorta to support the social infrastructure, such as continued economic, social and medical and disaster prevention, we started from the 2015 fiscal year for the large-scale renovation and repair business of road structures. In order to further permeate the need for this large-scale renewal / repair business, the common business name of each Expressway company was called "Expressway Renewal Project", and a logo was also created.

In the future, the Expressway renewal project will be in full swing, and construction will be carried out in each region with large-scale traffic restrictions, such as face-to-face traffic and road closures. Minimize the impact on customers by adopting new technology to shorten the construction period and using a mobile fence (Road Zipper® System) that can operate lanes according to traffic characteristics I will. In addition, we will cooperate with other Expressway companies so that our customers can fully understand them, and we will carry out publicity development of business understanding and construction announcements.

The "Expressway Renewal Project" will perform such work.

Replacement of floor slab *

Replace with a concrete slab with high durability.

- A floor slab is a structural member that directly supports an automobile or the like passing through a bridge and transmits the load to the girder.

Construction of floor slab waterproof layer

In order to prevent deterioration of the concrete floor slab, high-performance floor slab waterproofing is applied to the waterproof layer.

Girder reinforcement

Attach reinforcement members to the girders for increased durability.

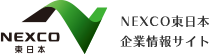

Invert * installation

Inverts are installed to improve the structure for tunnels that receive excessive force from around the tunnel, improving stability.

- Invert is to prevent deformation by installing semicircular concrete at the bottom of the road surface and making the tunnel shape circular.

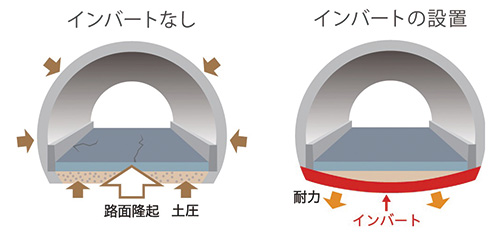

Construction of ground anchor *

In order to ensure long-term stability of the cut slope, we will construct a ground anchor with high anticorrosion performance.

- The ground anchor stabilizes the force that the cut slope is about to deform by driving a high-strength steel rod.

Realization of innovation by introducing SMH (Smart Maintenance Highway)

The SMH, Expressway in order to ensure the long-term "safety and security" of, to take advantage of the latest technologies, such as ICT and robotics, Expressway is a project to dramatically improve the productivity in the Asset Management.

In the first phase (introduced in 2020), we will develop SMH under the theme of "structure inspection", which is the basis of infrastructure management. Introducing inspection support tools such as high-resolution cameras, inspection robots, self-propelled measuring vehicles, recording work using mobile PC terminals, etc. to improve the efficiency of inspection work, and make decisions using business intelligence tools (BI) We will also promote Standard of processes. In addition, we will also utilize the latest technologies such as all-around road images and MR technology.

From 2020, we will begin to transform business processes in infrastructure management with the aim of providing Expressway sustainably.

Introducing SMH development tools that utilize ICT technology.

Road-eye®

High-precision measurement of damage on paved road surface and tunnel lining surface while traveling at high speed without traffic restrictions.

Mobile PC inspection support system

Data can be entered based on the history during on-site inspection. Furthermore, registration work after on-site inspection is unnecessary, improving productivity.

PRETES-e

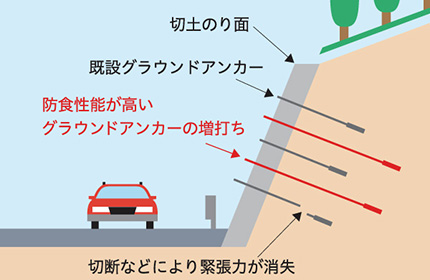

A training support tool that utilizes MR (Mixed Reality) technology. Understanding is improved by overlaying internal structures that are not actually visible on the structure at the site.

All-around road image system

Images with location information allow you to check and measure images without going to the site. It is used as a video information infrastructure by registering information tags necessary for road management.

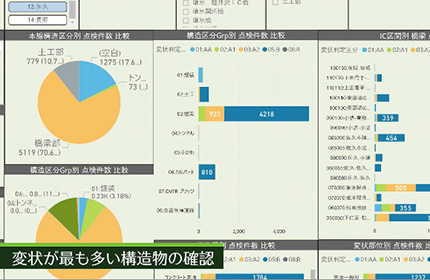

Visualization of inspection data by BI

Supports visualization of inspection data using Power BI and decision making in consideration of repair plans